MAXPULL’s “electropolishing” has improved!

![]() 2021/10/13

2021/10/13

“Sophisticated surface treatment” improves optimization for clean room

MAXPULL’s “electropolishing” has improved!

At MAXPULL MACHINERY & ENGINEERING CO., LTD., we were dissatisfied with the current product quality, as we conducted research and development every day to improve our product. From this process, we improved the polishing precision of the surface processing of MAXPULL stainless steel winch ESB / ERSB series and were able to improve the quality of our products.

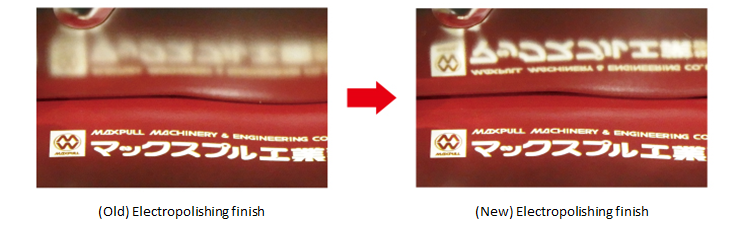

■ Improvement of beauty (glossiness)

The former electropolishing surface had a matte look, however, with the new electropolishing process, the finish is shiny as the buffing was successful.

Acquiring the gloss from buffing, dramatically improved the aesthetics and texture of the stainless steel equipment.

■ Complete removal of weld burn

The new electropolishing succeeded in completely removing weld burn. Removing weld burn or fine surface irregularities can make for a smooth surface that dirt and viruses are less likely to adhere. This makes the product ideal for washability and appropriateness in clean room, etc.

■ Electropolishing

The electropolishing means the processing to finish the glossy surface electrochemically by putting materials such as stainless steel into the electrolyte to pass electricity through a metal material to cause an electrolytic reaction and by preferentially dissolving and smoothing ultra-fine protrusions on the surface of metal materials. This process is excellent for polishing parts that are difficult to physically polish.

If you implement electropolishing to dissolve the metal surface of stainless steel, Cr (chromium) of oxide film covering the stainless steel surface (passive film) condenses to be regenerated into a nearly perfect passive film and higher corrosion resistant than before treatment can be obtained.